High-speed SDS D Series cutting nozzles typically feature optimized designs that enhance gas flow characteristics, such as smoother internal surfaces, precision-engineered contours, and efficient gas mixing chambers. These design enhancements help maximize the velocity of the supersonic gas jet, resulting in faster cutting speeds.

Increased Flow Rates:

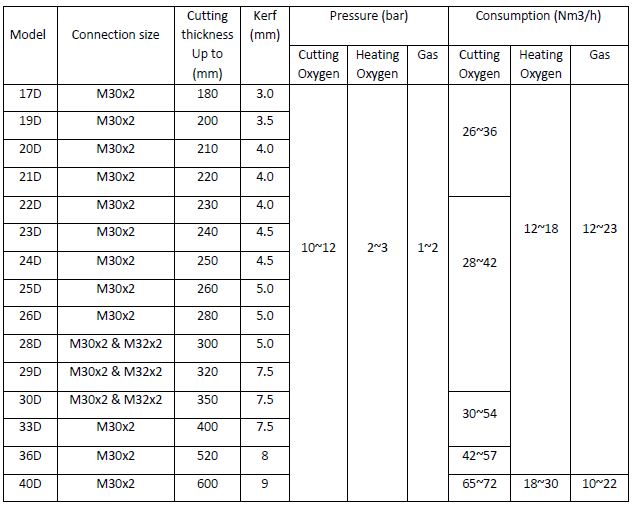

High-speed SDS D SERIES cutting nozzles often allow for higher flow rates of the cutting gases (such as oxygen and fuel gas) compared to standard nozzles. The increased flow rates contribute to greater material removal rates and improved cutting efficiency.

The company’s latest development is the Laval nozzle cutting nozzle, which is designed and manufactured based on aerodynamic separation. After on-site use, the cutting speed is significantly improved. The slit width is reduced by 20%. The cutting surface is smooth, and the phenomenon of slag hanging at the lower part of the cutting is greatly improved. The inner wall of the cutting nozzle cavity is plated with chromium and has a long service life.