Cutting thick stainless steel alloys (400mm to 700mm) with oxy-fuel methods is challenging due to refractory oxides that form and hinder cutting. These oxides have higher melting points than the base material. Powder cutting and powder scarfing techniques address this by injecting iron powder into the flame, which creates a lower melting point eutectic oxide at the cutting interface. This enhances the iron-oxygen reaction and facilitates cutting. The pre-heated iron powder ignites in the oxygen stream, generating heat and fluxing action, allowing effective oxidation of the base metal, similar to cutting carbon steel.

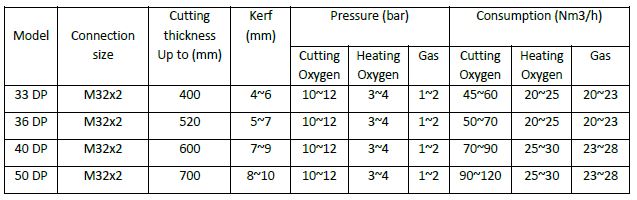

Technical specifications of the nozzle SDS-DP series Cutting Chart: